|

|

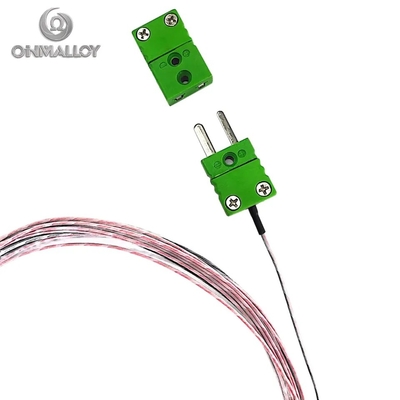

مقاومت حرارتی Rtd کابل ترموکوپل Pt100 حسگر درجه حرارت کوره گرما

|

جزئیات محصول:

پرداخت:

|

| نام: | ترموکوپل مقاومت حرارتی rtd pt100 | اندازه هادی: | 0.75mm2 (3*7/0.37mm) |

|---|---|---|---|

| عایق و مواد ژاکت: | فیلم کاپتون (حداکثر 200 درجه سانتیگراد) | شکل: | گرد |

| دقت: | کلاس I (T±4%) | محدوده دما: | -10 تا +260 درجه سانتیگراد |

| برجسته کردن: | کابل ترموکوپل Rtd,Pt100 حسگر دمای کوره گرما,کابل ترموکوپل مقاومت حرارتی,Pt100 Heat Furnace Temperature Sensor,Thermal Resistance Thermocouple Cable |

||

Thermal resistance rtd thermocouple pt100 heat furnace temperature sensor

Specifications

1.Style:Compensation Wire

2.Thermocouple RTD wire

3 wire stainless steel probe high temperature thermocouple RTD sensores PT 100

Thermocouple RTD wire Classification

1. Thermocouple level (high temperature level). This type of thermocouple wire is mainly suitable for thermocouple type K, J, E, T, N and L and other high temperature detection instrument, temperature sensor, etc.

2. Compensating wire level (low temperature level). This type of thermocouple wire is mainly suitable for compensating cable and extension wire of various thermocouples of type S, R, B, K, E, J, T, N and L, heating cable, control cable and so on.

| Thermocouple Variety and Index | ||

| Variety | Type | Measurement Range(°C) |

| NiCr-NiSi | K | -200-1300 |

| NiCr-CuNi | E | -200-900 |

| Fe-CuNi | J | -40-750 |

| Cu-CuNi | T | -200-350 |

| NiCrSi-NiSi | N | -200-1300 |

| NiCr-AuFe0.07 | NiCr-AuFe0.07 | -270-0 |

3 . Dimensions and Tolerance of Fiberglass Insulated Thermocouple Wire

Dimensions / Tolerance mm ) : 4.0+-0.25

Color code & initial calibration tolerances for thermocouple wire

| Thermocouple Type | ANSI Color Code | Initial Calibration Tolerances | ||||

| Wire Alloys | Calibration |

+/- Conductor |

Jacket | Temperature Range |

Standard Limits |

Special Limits |

|

Iron(+) vs. Constantan(-) |

J | White/Red | Brown |

0°C to +285°C 285°C to +750°C |

±2.2°C ± .75% |

±1.1°C ± .4% |

|

CHROMEL(+) vs. ALUMEL(-) |

K | Yellow/Red | Brown |

-200°C to -110°C -110°C to 0°C 0°C to +285°C 285°C to +1250°C |

± 2% ±2.2°C ±2.2°C ± .75% |

±1.1°C ± .4% |

|

Copper(+) vs. Constantan(-) |

T | Blue/Red | Brown |

-200°C to -65°C -65°C to +130°C 130°C to +350°C |

± 1.5% ±1°C ± .75% |

± .8% ± .5°C ± .4% |

|

CHROMEL(+) vs. Constantan(-) |

E | Purple/Red | Brown |

-200°C to -170°C -170°C to +250°C 250°C to +340°C 340°C+900°C |

± 1% ±1.7°C ±1.7°C ± .5% |

±1°C ±1°C ± .4% ± .4% |

Color Code & Initial Calibration Tolerance for Extension Wire

| Extension type | ANSI Color Code | Initial Calibration Tolerances | ||||

| Wire Alloys | Calibration |

+/- Conductor |

Jacket | Temperature Range |

Standard Limits |

Special Limits |

| Iron (+) vs. Constantan(-) | JX | White/Red | Black | 0°C to +200°C | ±2.2°C | ±1.1°C |

| CHROMEL (+) vs. ALUMEL (-) | KX | Yellow/Red | Yellow | 0°C to +200°C | ±2.2°C | ±1.1°C |

| Copper(+) vs. Constantan(-) | TX | Blue/Red | Blue | -60°C to +100°C | ±1.1°C | ± .5°C |

| CHROMEL(+) vs. Constantan(-) | EX | Purple/Red | Purple | 0°C to +200°C | ±1.7°C | ±1.1°C |

PVC-PVC Physical Properties

| characteristics | Insulation | jacket |

| Abrasion Resistance | Good | Good |

| Cut Through Resistance | Good | Good |

| Moisture Resistance | Excellent | Excellent |

| Solder Iron Resistance | Poor | Poor |

| Service Temperature |

105℃ continuous 150℃ single |

105℃ continuous 150℃ single |

| Flame Test | Self-extinguishing | Self-extinguishing |

![]()

تماس با شخص: Mr. Qiu

تلفن: +8613795230939

-

پلاگین ترمومتر کرومل آلومل

-

درجه حرارت پیچ نوع K ترموکوپل سیم جوش / کابل جبران

-

نوع سیم کشی تفلون کابل RTD 7 X 24 AWG را با سپر فولادی ضد زنگ

-

سیم کشی ترموکوپل NiCr / NiAl با درجه حرارت بالا 1.3mm X 2 AWG 16 نوع K

-

+ کابل کروم / آلومل کابل کشی نوع K با عایق سیلیکا Vitreous

-

کابل کلاس K با دمای بالا | 2*0.6 میلیمتر جفت تابیده | ANSI MC96.1 | -270 درجه سانتیگراد تا 1372 درجه سانتیگراد